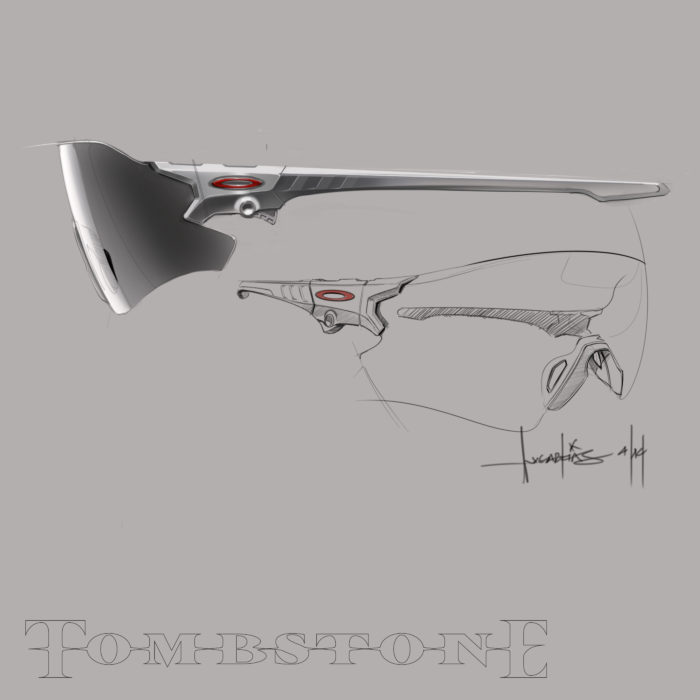

Unobstructed vision maintains job focus. Let’s be honest, the demands of any athlete or military professional are intense. At times, one only has but a split second to make a correction, dodge an obstacle, or take a shot. With respect to eyewear, the ability to see with no distractions is paramount. Our development of the Oakley SI Tombstone using SMI Eyetracking Technology, lens color technology, and lens interchange, changed the course of vision for the professionals we serve.

The Sport of Shooting

In 2013 we saw a large growth and insurgence of the recreational and competitive shooting market, specifically 3-Gun. 3-Gun competition is a timed shooting event that requires the competitor to shoot with a pistol, carbine, and shotgun. Various paper, steel, and clay targets appear as competitors maneuver through various obstacles. Recognizing a viable market, with common problem statements to our military and law enforcement community, we set out to make our mark.

Shooting is an extremely focused and vision dominant sport. The ability to quickly identify targets and maintain a clear sight picture has enormous bearing. Back at the Oakley Bunker, our team asked one another, ‘what tools do we have to really measure and assess ‘clear and unobstructed vision’?” As technology advances so do the tools for which to capture data and solve problems.

Field Testing with the Army Marksmanship Unit (AMU)

In 2013, SensoMotoric Instruments (SMI), based in Germany, invented a product called Eye Tracking Glasses. Based on pupil and corneal reflections from infrared light sources, the camera built into the eyewear detects face, eye, and pupil, to calculate eye movements, gaze direction and points of focus. In layman’s terms, it can detect where you are looking during any given activity. Naturally, our Mad Science team had to have one of the first five pairs ever made.

Armed with new technology, we set out to understand the complex problem statements that faced competitive shooters. With any test group, we sought the most proficient and top tier: The Army Marksmanship Unit (AMU). Based in Ft. Benning, GA, the AMU is the premier shooting unit within the entire military. The unit has multiple teams focused on different shooting disciplines such as Action Shooting (3-Gun), Shotgun, Service Pistol, Service Rifle, and additional training teams. With multiple Olympic Medals within their headquarters, the AMU was certainly the group for our test bed.

Krilling Range is home to the Action Shooting Team of the AMU. Upon arrival, we began work with several of the top marksman to include Daniel Horner, Tyler Payne, and Joel Turner. We talked with all shooters, watched them shoot, asked questions, and of course got plenty of trigger time ourselves.

Field of View

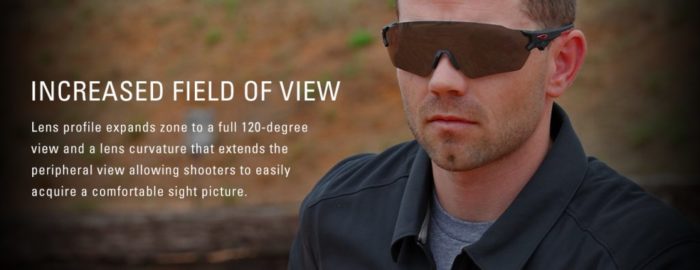

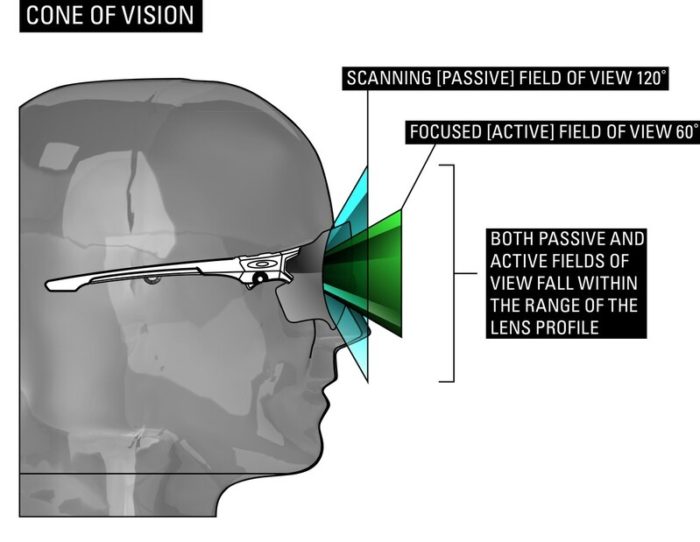

What quickly became evident, and confirmed using the Eye Tracker, was each shooter utilized the entire upper periphery of the lens. Maintaining a very forward posture, a shooter does a head tilt to acquire proper sight alignment, thereby using the upper portion of any lens about 80% of the time. It was clear that the upper periphery needed to be free and clear of any frame, but also clear of any light distractions. After spending time with the Action Shooting Team, we then received the same confirmation with the Shotgun Team.

The impact of this data on Tombstone was a rimless design. We did not want any frame to impact field of view. Additionally, the lens shape extended above the brow. This design feature afforded the shooter an ability to have zero light gaps and really ‘live within the lens.’

A Testbed for Prizm

Understanding requirements on field of view, we set out to understand additional problem statements associated with shooting. Like many activities performed outside, one experiences changes in light and environment. For the Action Shooting Team, the targets used were steel, paper, and sometimes clay pigeons. The environment changed from woodland to desert based on the event location, or bright light to low light based on weather or time of day. With a dynamic competition environment, the ability to change lenses was of significance. Additionally, having a portfolio of lenses that enhanced, and contributed toward, performance was of even greater consequence.

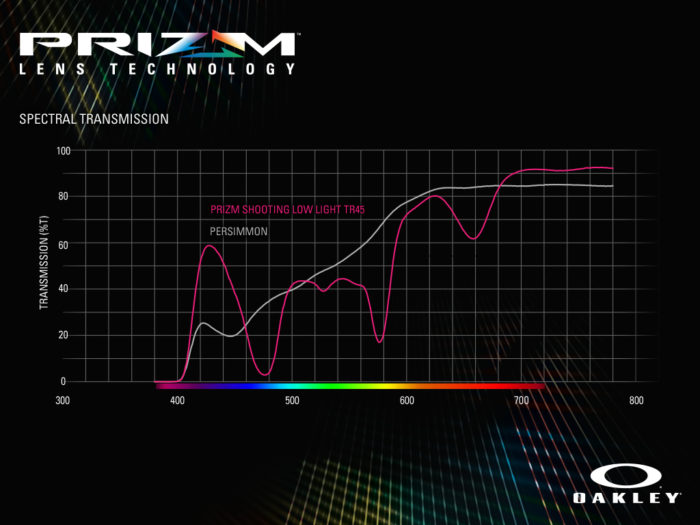

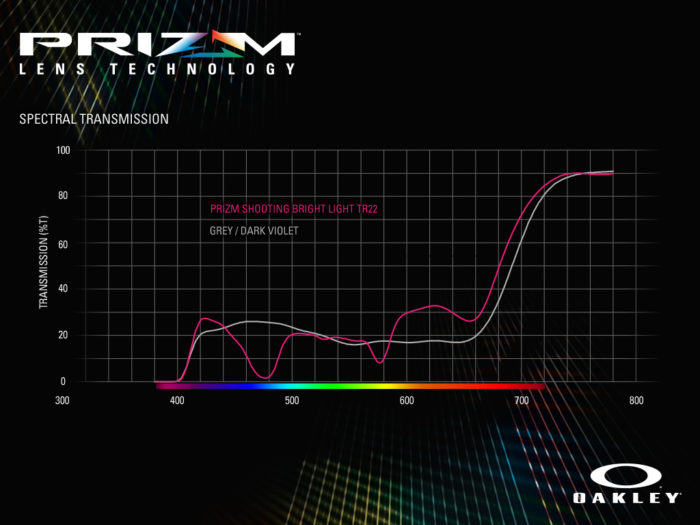

With a long history in lens optics, Oakley has always been pushing the boundaries of vision. Drawing scientific influence from the military laser lens program, in 2013 Oakley had been toying with the concept of ‘dye loading,’ for new applications. Every Oakley lens is composed of polycarbonate, which is molded, and cut, carefully into the shape of a lens. In the process called ‘extrusion,’ clear polycarbonate is combined with a specific dye mixture to block or enhance specific wavelengths of light. A laser lens blocks specific wavelengths of light, mostly infrared or non-visible spectrum, in order to protect the individual from harm. Taking it a step further, we discovered that with certain dye chemistry we could block specific light in the visible spectrum. This new technology we dubbed ‘Contrast Enhancement (CE).’

Prizm TR22 & TR45

The AMU operated in the visible light spectrum. They encountered lots of different environments and targets. Using an optical spectrometer, a device for measuring wavelengths of light, we prototyped multiple lens options for the shooters to try. Through a long and deliberate process of trial and error, we settled on two lenses: TR45 and TR22. With a similar color profile, the lenses thrived in very arid environments, separating any brown and accentuating the targets. The TR45, a lens suited for overcast or low light conditions, has an overall visual light transmission (VLT) of 45%, while the TR22 was ideal for bright light conditions with a VLT of 22%. These two options armed the AMU with a lens selection for any light condition. It was but a couple years later this lens technology would carry the trade name Prizm™.

Ironically, the environments and targets the AMU encounters are not terribly different from the Special Operations community. During our trials with the AMU at Ft. Benning, GA, we spent numerous days with the 75th Ranger Regiment to evaluate lens color profiles. Different light conditions and different targets were consistent themes. When tested, TR45 and TR22 were universally appealing. The lenses are now part of the Special Operations Eyewear Program (SOEP).

Lens Exchange

Field of view understood, lens options understood, next up: Lens Exchange. With multiple lens options in their pocket, a simple and easy way to exchange the lens is needed. Stemming from our history with Switchlock™, we decided to create something even more robust, yet simple. We looked no further than a handgun for inspiration. The mechanism of inserting and releasing a magazine into a pistol, or carbine, was the secret. Insert a magazine into the well, it slides up and locks securely into place. Push the magazine release and it can fall or be pulled out.

Lens exchange for Tombstone is designed no different. Each end of the lens can push into a well and lock into lace. To release the lens, you simply push on the lens release and the lens can be pulled out. This simple and easy-to-use lens exchange mechanism afforded shooters a quick and seamless process. Additionally, the process is completed without smudging the lenses with fingerprints, a common request heard amongst shooters.

Tombstone is the destination, but the journey traveled to arrive there was even more profound. Tombstone is an amazing product for the reason of deliberate application of problem solving. The product addresses each single need of that consumer. Through the design, testing, and evaluation we learned lessons on field of view, lens development, and lens exchange. Process’, data, and technology that is applied across our military and law enforcement personnel, and consequently to every other commercial sport. Though a product for a niche sport, Tombstone reveals that everything can and will be made better.