Oakley’s creation of the Laser Lens gave rise to the origins of Prizm Lens Technology. It is a serendipitous occurrence. A product, designed to protect soldiers from harmful infrared light, helped create a groundbreaking technology that revolutionized performance to enhance vision.

Table of Contents

How Prizm™ Lens Technology Began

For those unfamiliar with the danger of harmful infrared light to the eyes, or even visible light, it is relatively simple. Sunlight contains red, orange, yellow, green, blue, and violet rays of light.

Combined, this spectrum forms what we call “white light”, or sunlight. But on both ends of the light spectrum there is Ultraviolet (UV) light and Infrared (IR) light. Both types of lights are deemed ‘high energy,’ and are potentially harmful. UV light you cannot see but is responsible for suntans, sunburns, supports vitamin D absorption, and is also the cause for ailments like macular degeneration and cataracts. It is why you wear sunglasses with UV blocking technology. IR light you cannot see either, but when in a concentrated form can be damaging to the eyes.

Laser Protective Lens (LPL)

The military has long used IR marking devices to support modern warfare. Operations conducted at night, provide forces the elements of surprise. Night Vision Devices (NVGs), provide soldiers the operational capability to see in the IR spectrum. Marking tools such as an IZLID, and SOFLAM are common. An IZLID is a small handheld IR marking device that marks enemy forces for ground personnel and aircraft. A SOFLAM is a higher-powered marking device that helps deploy laser-guided munitions to a target. These tools, while effective, can also be dangerous to personnel. With a high concentration of energy, even the refraction of this IR laser can cause eye damage.

To protect soldiers from any refraction or direct impact from the lasers, eye protection is needed. With any well-defined problem statement and end-user input, Oakley applied years of lens development to create a solution.

Creating a Laser Protective Lens (LPL) starts with a process called extrusion. Every Oakley lens is composed of polycarbonate. Polycarbonate is molded, and cut, carefully into the shape of a lens. Through a process of extrusion, clear polycarbonate is combined with dye to block or enhance specific wavelengths of light. With careful measurements of the IR light spectrum, trial and error, and laboratory testing, Oakley was able to create an LPL that would block the IR wavelengths that cause harm but still maintain clarity to see other colors. While green in physical color, the LPL affords the user the ability to see all the other colors in the light spectrum, as to maintain and afford all situational awareness. The Oakley LPL is available to all Conventional and Special Operations Forces.

The Next Step

Passionate curiosity has always been part of the Oakley DNA. Logically, the team began to wonder, “if we can block wavelengths in the IR spectrum, why couldn’t we block some colors in the visible spectrum?’ With our history in sport performance, we knew right away that specific sports and activities have dominant colors. What if we ‘tuned’ the lens to create contrast among the important colors and minimize the others? Asking challenging questions is the beginning of every innovation.

We quickly discovered that with certain dye chemistry we could block specific light in the visible spectrum. This new technology we dubbed ‘Contrast Enhancement (CE).’

Oakley Standard Issue was quick to begin iterations with CE. After all, if a soldier can ‘see more,’ that could mean the difference between life and death. Ft. Benning was the first stop of many to test early prototypes. Time spent with the Army Marksmanship Unit (AMU), the 75th Ranger Regiment, and many more, proved immensely valuable. With a heightened operational tempo in the middle east, a historically dry and arid environment, soldiers have a considerably basic lens offering. Traditionally, a clear lens, and grey lens is issued. Those who could afford an out-of-pocket expense might buy a transition, or photochromic lens. Clear is ideal for night, and grey is used during bright conditions during the day. Grey essentially neutralizes most color.

TR22 & TR45

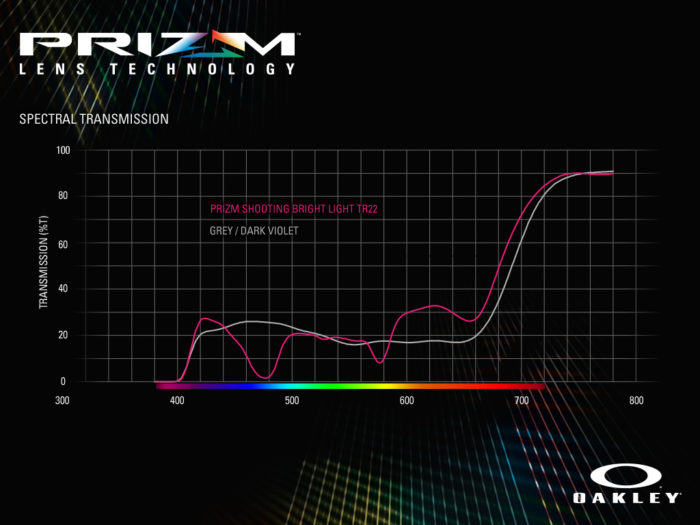

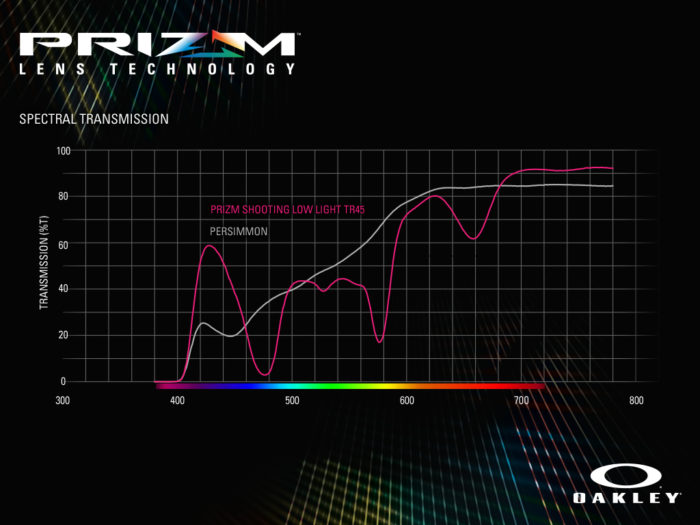

Using an optical spectrometer, a device for measuring wavelengths of light, we prototyped multiple lens options for the shooters and soldiers to try. These evaluations occurred both stateside and OCONUS. Through a long and deliberate process of trial and error, two variations were made: TR45 and TR22. With a similar color profile, the lenses thrived in very arid environments separating any brown and accentuating movement. The TR45, a lens suited for overcast or low light conditions, has an overall visual light transmission (VLT) of 45%, while the TR22 was ideal for bright light conditions with a VLT of 22%. When tested, TR45 and TR22 were universally appealing, and became formally known as ‘Prizm Shooting.’

The development has not ended there. After the release of Prizm Shooting in 2014, Oakley went on to release multiple categories of Prizm for sport performance to include Prizm Baseball, Prizm Golf, Prizm Road and more. Oakley Standard Issue went on to develop Prizm Maritime in collaboration with our military and law enforcement personnel.

Prizm Shooting is now authorized for wear under the Special Operations Eyewear Program (SOEP).

Products that came from the Origins of Prizm Lens Technology

Discover additional Prizm Lens Technologies with Prizm Grey Lenses, Prizm Maritime Lenses, and Prizm Snow Lenses.